charpy v notch charpy impact test specimen|charpy v notch sample size : wholesaler In materials science, the Charpy impact test, also known as the Charpy V-notch test, is a standardized high strain rate test which determines the amount of energy absorbed by a material during fracture. Absorbed energy is a measure of the material's notch toughness. It is widely used in industry, since it . See more Resultado da 7 de nov. de 2023 · ABC: Michael, Gedeilson, Habraão, Fabrício e Jhonnathan; Daniel, Ramon e Matheus Anjos; Andrey, Anderson Cordeiro .

{plog:ftitle_list}

Avenida Francisco Monteiro, 702 - Vila Albertina, Ribeirão Pires, São Paulo. site: http://www.facebook.com/pg/evoqueacademia/photos/?ref=page_internal | .

In materials science, the Charpy impact test, also known as the Charpy V-notch test, is a standardized high strain rate test which determines the amount of energy absorbed by a material during fracture. Absorbed energy is a measure of the material's notch toughness. It is widely used in industry, since it . See moreIn 1896, S. B. Russell introduced the idea of residual fracture energy and devised a pendulum fracture test. Russell's initial tests measured un-notched samples. In 1897, Frémont . See moreThe quantitative result of the impact tests the energy needed to fracture a material and can be used to measure the toughness of the material. There is a connection to the yield strength but it cannot be expressed by a standard formula. Also, the . See moreAccording to ASTM A370, the standard specimen size for Charpy impact testing is 10 mm × 10 mm × 55 mm. Subsize specimen sizes are: . See more

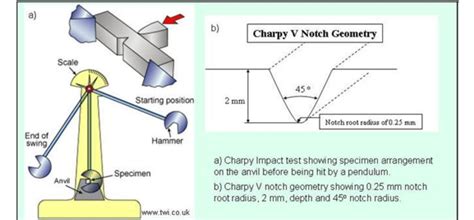

• Izod impact strength test• Brittle• Impact force See moreThe apparatus consists of a pendulum of known mass and length that is dropped from a known height to impact a notched specimen of material. The energy transferred to the . See more

The qualitative results of the impact test can be used to determine the ductility of a material. If the material breaks on a flat plane, the fracture was brittle, and if the material breaks with . See moreThe impact energy of low-strength metals that do not show a change of fracture mode with temperature, is usually high and insensitive to temperature. For these reasons, impact tests . See more

charpy v notch toughness

This makes Charpy testing a popular choice for assessing the toughness of metals like steel, as well as polymers, composites, and ceramics. Here’s how the process works: The test .The ISO 148-1 standard specifies the Charpy (U-notch and V-notch) impact test on metals for determination of the impact strength. The impact strength of a material is an important characteristic for applications in pipeline construction .The Charpy impact test, also known as the Charpy V-notch test, is a high strain-rate test that involves striking a standard notched specimen with a controlled weight pendulum swung from a set height. The impact test helps measure the .

The history of Charpy V-notch impact testing dates back to the early 1900s when French engineer Georges Charpy developed a standardized method for testing the impact toughness of materials, particularly metals. His .

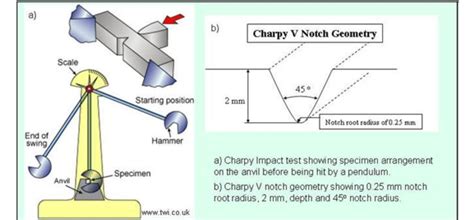

The ASTM E23 standard describes notched bar impact testing of metals according to Charpy and Izod.For the test, a notched metal specimen is broken in half using a pendulum hammer. The ASTM E23 standard describes the .Full size impact specimens are 10mm x 10mm x 25mm. The minimum controlling thickness for a Charpy V notch specimen is the 10mm thickness by 55mm long. . STM and ISO Charpy V Notch Tests utilize the same test .Here’s how the process works: The test specimen, typically 55 mm long and 10 mm square with a 2 mm deep V-notch, is positioned horizontally in the Charpy impact testing machine. The Charpy impact test specimen notch faces away from the pendulum, which swings down from a set height to strike the sample. The Charpy test is a high loading rate test that measures the energy absorbed during fracture, hence providing an indirect measure of impact toughness. For a Charpy machine to maintain an accurate absorbed energy scale, periodic verification with .

The Charpy specimen may be used with one of three different types of notch, a 'keyhole', a 'U' and a 'V'. The keyhole and U-notch are used for the testing of brittle materials such as cast iron and for the testing of plastics. The V-notch specimen is the specimen of choice for weld testing and is the one discussed here. The current British .Mechanical testing of welds. Philippa Moore, Geoff Booth, in The Welding Engineer s Guide to Fracture and Fatigue, 2015. 9.5 Charpy testing. The Charpy test measures the energy absorbed when a notched bar of material is struck with a fixed-weight pendulum swung from a given height. The absorbed energy (in joules) is also referred to as the impact toughness of the material.Understanding the critical importance of Charpy Impact Testing sets the stage for delving into its step-by-step procedure and intricacies – an insightful journey that demystifies this essential method for assessing material toughness. Step-by-step Procedure of a Charpy Impact Test. Performing a Charpy impact test involves several important steps.

Impact testing, including charpy impact testing, can determine material toughness and yield strength. Impact testing at Laboratory Testing Inc. is performed . Cutting the specimen is the second step in preparing U- and V-notched specimens for Charpy and Izod impact testing. The material is precisely cut into standardized dimensions during this process. Standard Dimensions. Charpy Test Specimens: Length: 55 mm. Width: 10 mm. Thickness: 10 mm. Izod Test Specimens: Plastic Specimens: 64 mm x 12.7 .ESIS TC5, “Proposed Standard Method for Instrumented Impact Testing of Sub-Size Charpy V-Notch Specimens of Steels” (Annex C), Draft 10a, 23/5/02 [10] Lucon E., Round-Robin On Instrumented Impact Testing Of Sub Size Charpy-V Specimens: Results Of Phase 1”, ESIS TC5 Instrumented Impact Testing, Final Report, 2 April 1998 [11]

The Charpy V-notch impact test is performed by machining ‘V’ notch in the centre of the standard test specimen and the test specimen is fractured at a test temperature by a swinging pendulum of a known potential energy. The test specimen absorbs portion of the energy to fracture and this absorbed energy is indicated by the machine.

It is used more as a comparative test rather than a definitive test. Charpy Test Specimens. Charpy test specimens normally measure 55x10x10mm and have a notch machined across one of the larger faces. The notches may be: • V-notch – A V-shaped notch, 2mm deep, with 45° angle and 0.25mm radius along the base

The Certification of Two New Master Batches of V-Notch Charpy Impact Toughness Specimens in Accordance with EN 10045-2: 1992 . Steel-Charpy Impact Test (V-Notch),” International Organization for Standardization, Genève, 1983. 9. McCowan, C. N., .4.3 The Charpy V-notch impact test in relation to other tests. 4.4 Factors influencing impact properties. 4.5 The Charpy V-notch impact test as a powerful tool for delivery control in steel specifications. 5 Information to be gained from the impact test. 6 Subsize test pieces. What Is the Charpy Impact Test? The Charpy impact test, sometimes called a V-notch test, is a comparative-style test used to define a material’s impact strength by determining how much energy is required to .

The Charpy impact test, especially the Charpy V-notch (CVN) technique is one of most commonly used toughness tests. Charpy Impact Test. . multiplied by the weight of the pendulum is a measure of the energy absorbed by the . 1. Introduction. Impact energy characterizes the ability of a structure to consume energy through deformation and fracture under impact load. The impact energy A k, a value measured by the Charpy impact test, is mainly used to control the quality of metallurgical and thermal processing products and determine the ductile-brittle transition temperature of .

charpy v notch testing standard

The Charpy V-notch impact is a mechanical test for determining qualitative results for material properties and performance which are useful in engineering design, analysis of structures, and materials development. EQUIPMENT • Charpy V-notch test specimens of 6061-T6 aluminum and 1018 (hot rolled) or A36 steel

Charpy Impact Test Specimen Dimensions. A Charpy test specimen, which is placed horizontally into the machine, is typically a 55 x 10 x 10mm (2.165" x 0.394" x 0.394") bar with a notch machined into one of the faces. . Note: When Izod specimens are to be machined to ASTM E23 the sample will be a single notch specimen for round samples with .Charpy impact testing (also known as a Charpy V-Notch test) is a valuable method to determine the amount of energy a material absorbs during fracture. . According to ASTM A370, [12] the standard specimen size for Charpy impact testing is 10 mm × 10 mm × 55 mm. Request a Quote. PHYSICAL TESTING LAB SERVICES. Abrasion (Taber) Adhesion (Peel .3.2.2 Charpy V-notch impact tests may be carried out at ambient or lower temperatures in accordance with the specific requirements given in subsequent Chapters of these Rules. Where the test temperature is other than ambient, the temperature of the test specimen is to be controlled to within ±2°C for sufficient time to ensure uniformity throughout the cross-section of .

In order to develop the small specimen technology in Charpy impact testing, the effects of V-notch dimensions on the test results were investigated for miniaturized specimens of a ferritic steel, Japanese Ferrite/Martensite Dual Phase Steel (JFMS). The miniaturized Charpy specimens had four different square cross-sections of 3.3, 2, 1.5 and 1 mm, and each of them .Charpy impact testing was initially adopted for testing metals and then used in many early impact studies on FRP composites. The energy absorption and dissipation during the impact event as well as the failure mode can be tested. The specimen is usually in the form of a thick beam with or without a notch and is supported freely at two ends, as shown in Fig. 3 (a).

ISO 148-1 U-Notch pendulum testing is the European standard equivalent to ASTM E23 Charpy Impact testing.Both specimens use 10mm x 10mm x 55 mm specimens. Where the 45° V notch is required in the ASTM specification, it is replaced by 2mm or 5mm deep U notch geometry in the ISO specification.The stress concentration is less severe and has been found .The Charpy test is a pendulum-based test introduced by Georges Charpy and S. B. Russell. The test was valuable in understanding the material fracture in ships during world war II. The Charpy test consists of a pendulum and a hammer of known mass attached to it. The pendulum swings and hits the notched specimen to observe the energy transfer. 5.3 For this test method, the energy lost by the pendulum during the breakage of the specimen is the sum of the energies required to initiate fracture of the specimen; to propagate the fracture across the specimen; to throw the free ends of the broken specimen (toss energy); to bend the specimen; to produce vibration in the pendulum arm; to produce .

testo 350 xl flue gas analyzer

charpy v notch testing requirements

Como a maioria dos jogos de Crash, o apostador deve somente realizar sua aposta inicial, que varia de R$ 1 até R$ 25. Escolher seu multiplicador e esperar o começo do jogo com sua bet. Spaceman é o tipo de jogo que faz . Ver mais

charpy v notch charpy impact test specimen|charpy v notch sample size